The goal is to provide inspection on the bottom face of pipes to identify possible damages to the external cover. The inspections are performed on the bottom face area because these are spots where the pipes are working constantly with the oscillation of the vessel/platform.

Usually pipes form trenches up to 2.5 meters deep where there was extensive contact with seabed and an inspection is necessary to verify if there is any damage.

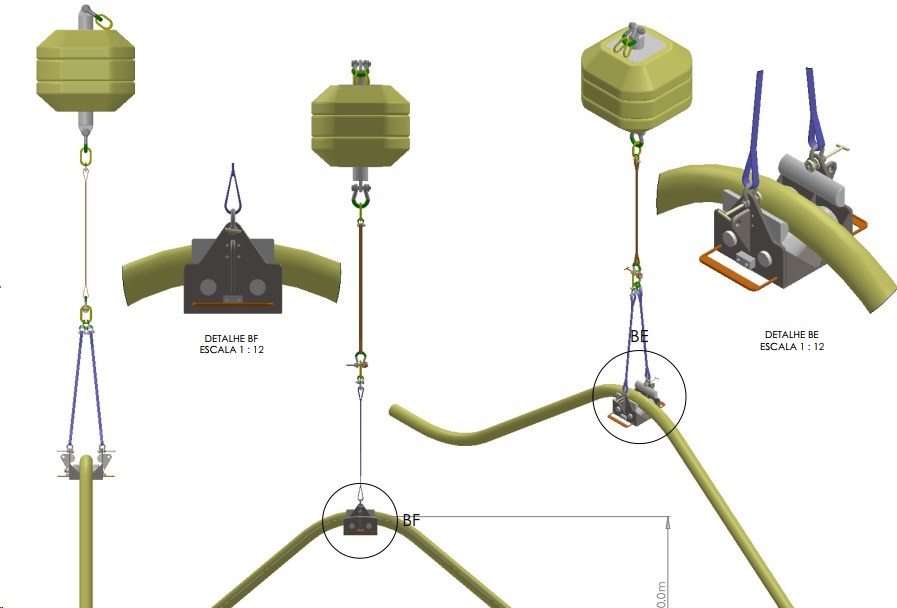

During the operation the pipe is lifted with a cradle with rollers through a crane or floaters limiting to the lifting height according to the construction of each pipe. A calculation is made to define the maximum lifting height and admissible workload so as to not risk damaging the pipe.

After lifting, a generation inspection tool (FIGI) is installed. With the tool positioned and the ROV hydraulically connected to the tool, begins the inspection in UEP direction or R/F connection.